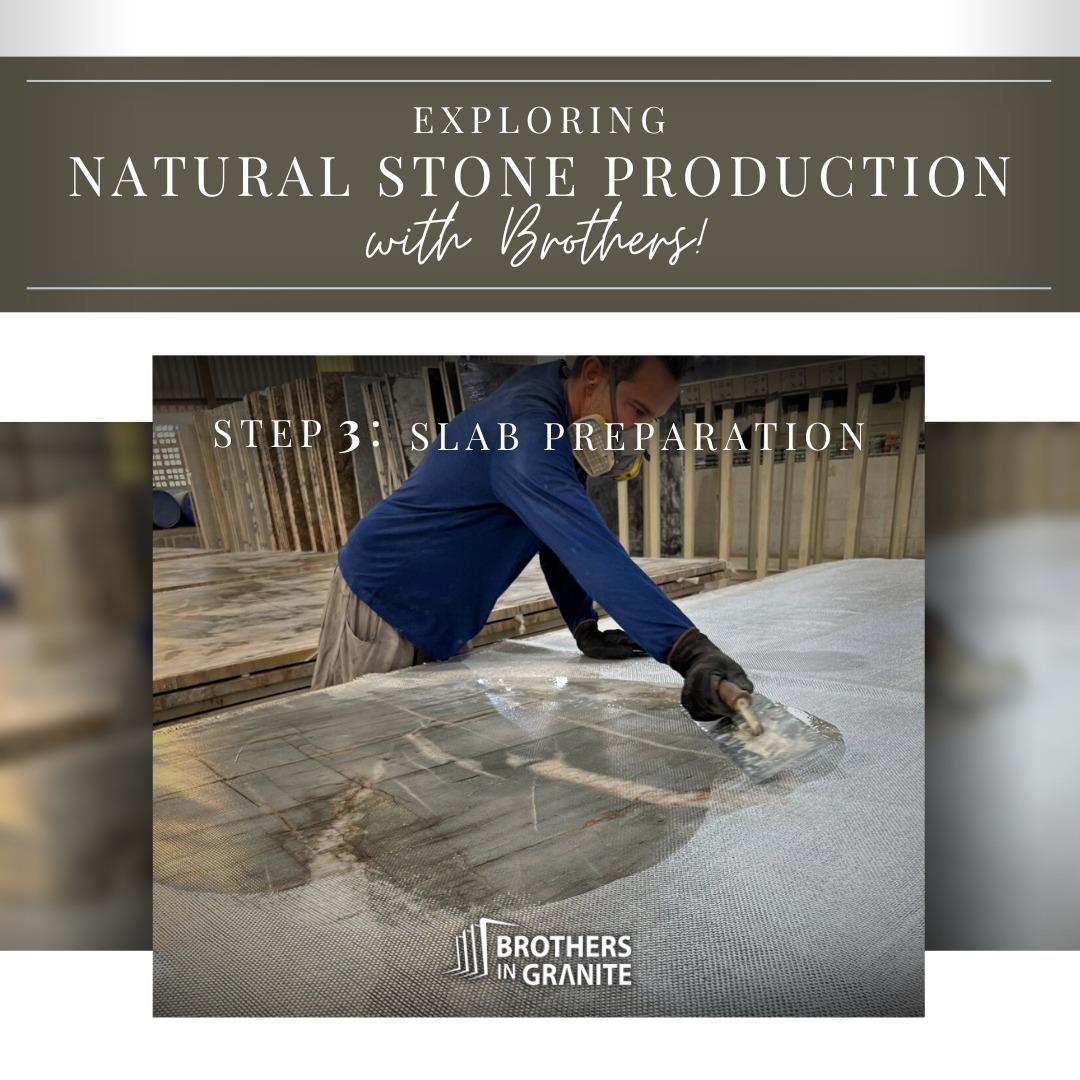

Blog Exploring Natural Stone Production with Brothers - Step 03: slab preparation!

03/26/2024

Revealing the Unseen: The Intriguing Resining process of Natural Stone is our next step - Slab Preparation!

At Brothers in Granite we’ve been in the natural stone business for a long time.

We know the hard work that goes into every project and while we still love to see the beautiful finished products that leave our factory every day we know that the true craftsmanship is invisible to the end user. Come behind the scenes and learn some steps in our production process that almost no one gets to see!At Brothers in Granite we’ve been in the natural stone business for a long time.

We’ve previously showed you how raw slabs are cut from the block of quarried stone. These new slabs are taken to our resining facility where they’re carefully laid horizontally. All natural stone is full of voids - fissures and holes and natural remnants from their formation. The resining process is how we address those areas to make the stone suitable for fabrication.

This is a several step process. Epoxy resin is used liberally on the back of the slab along to fill imperfections and to create a smooth surface area for the next step, in which vinyl mesh is cut to size and laid across the back of the slab. This gives the stone extra strength that allows it to be safely moved, cut, and fabricated. This mesh also gives some protection to the stone fabricators in case of a sudden break during transportation.

One the resins and mesh are dry, the slab goes through an initial quality assurance step before being readied for the next step of the process - polishing! Stay tuned for more information about that soon!