Blog Cristallo Azzure - Production Process

11/15/2023

At Brothers in Granite we’re always refining our production processes to bring you the highest quality natural stone possible. We wanted to share some of these processes with you and help you understand the efforts from our team that go into producing our showpiece colors, the natural masterpiece that is Cristallo Azzure.

Cristallo Azzure quartzite isn’t born as an exceptional natural stone, the finished product is a result of a meticulous process that begins with the selection of raw blocks from selected quarries that then undergo several specialized processes that lead to the beautiful finished slabs you see online. Join us as we detail those steps for you below.

Quarry:

The journey starts with a meticulous block selection. Our team of expert buyers examines each block of Cristallo Azzure to ensure that only the best ones are chosen. This rigorous selection process ensures that each stone meets our high quality standards. The majority of blocks are rejected during this stage as we identify quality defects that can’t be corrected during the resin application or polishing steps.

Cristallo Azzure quartzite isn’t born as an exceptional natural stone, the finished product is a result of a meticulous process that begins with the selection of raw blocks from selected quarries that then undergo several specialized processes that lead to the beautiful finished slabs you see online. Join us as we detail those steps for you below.

Quarry:

The journey starts with a meticulous block selection. Our team of expert buyers examines each block of Cristallo Azzure to ensure that only the best ones are chosen. This rigorous selection process ensures that each stone meets our high quality standards. The majority of blocks are rejected during this stage as we identify quality defects that can’t be corrected during the resin application or polishing steps.

Cutting:

After the best blocks are selected they’re sent to Brothers factory to be cut into the desired 2-or-3 centimeter thickness. This is done with a state-of-the-art diamond multi-wire saw that uses diamond coated wires to cut through the rock. We use diamond on the wires as natural quartzites are so physically hard that something even harder is required to cut through them!

Fun fact: In the past, a gang-saw with a huge spinning blade was used and it could take an entire week to cut a block of very hard stones, like Cristallo Azzure, into slabs. With the current generation of multi-wire saws the whole process can be completed in 6 to 8 hours!

After the best blocks are selected they’re sent to Brothers factory to be cut into the desired 2-or-3 centimeter thickness. This is done with a state-of-the-art diamond multi-wire saw that uses diamond coated wires to cut through the rock. We use diamond on the wires as natural quartzites are so physically hard that something even harder is required to cut through them!

Fun fact: In the past, a gang-saw with a huge spinning blade was used and it could take an entire week to cut a block of very hard stones, like Cristallo Azzure, into slabs. With the current generation of multi-wire saws the whole process can be completed in 6 to 8 hours!

Initial Production Steps:

Before starting the production process our team of experts identifies any defects in the material. Natural pinholes and cracks are prevalent in this type of raw unfinished stone. During this part of the job we’ll fill any large holes with smaller pieces of stone from the same quarry mixed with a resin binder.

Before starting the production process our team of experts identifies any defects in the material. Natural pinholes and cracks are prevalent in this type of raw unfinished stone. During this part of the job we’ll fill any large holes with smaller pieces of stone from the same quarry mixed with a resin binder.

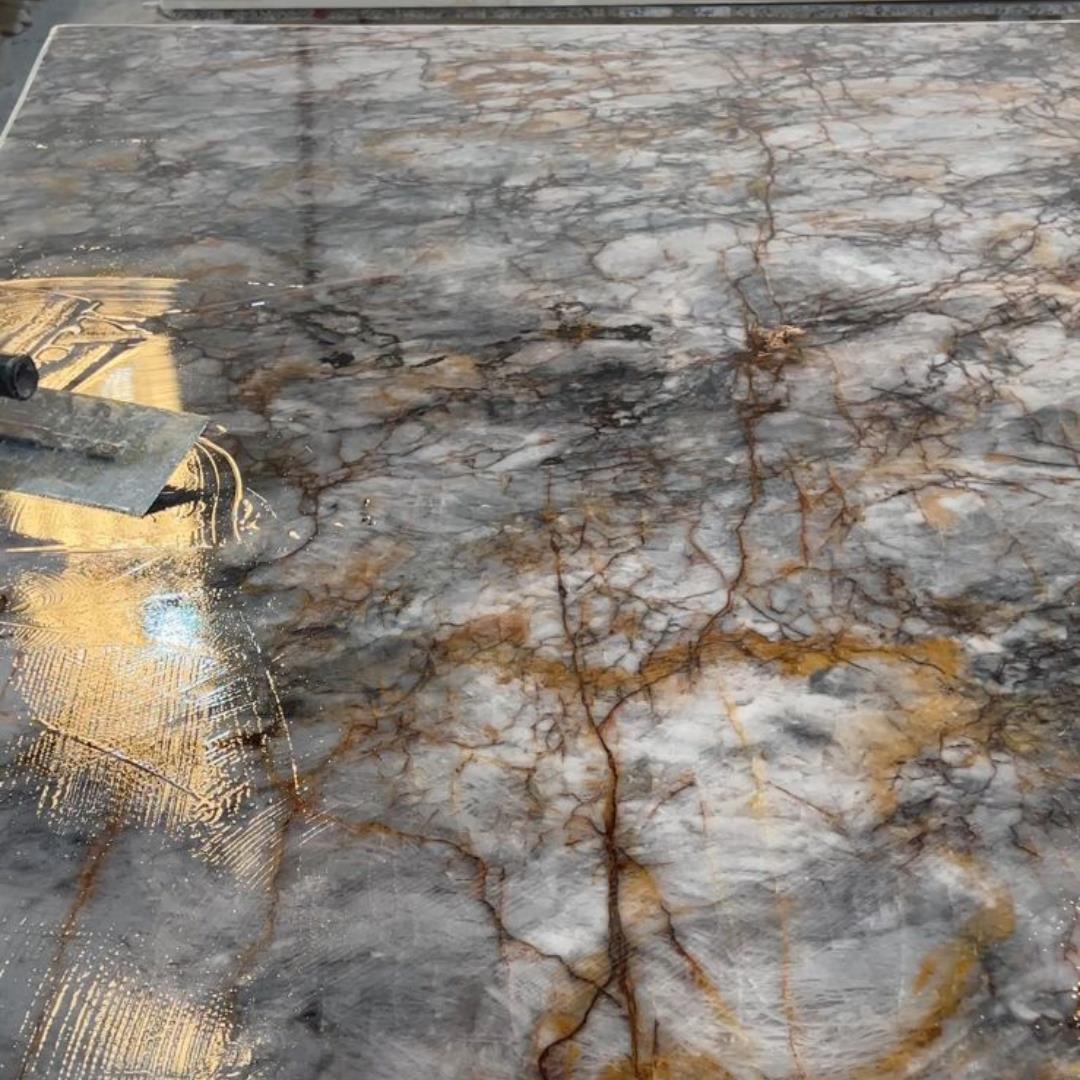

Resin Application:

Now we begin the protective resin application proper. This involves applying another layer of high-quality resin to each slab. This resin is specifically produced for this type of material and is imported by Brothers from Italy. This thick layer of resin is left to dry for 24-to-72 hours until it’s completely hard, leaving the stone much more durable than it was before.

Now we begin the protective resin application proper. This involves applying another layer of high-quality resin to each slab. This resin is specifically produced for this type of material and is imported by Brothers from Italy. This thick layer of resin is left to dry for 24-to-72 hours until it’s completely hard, leaving the stone much more durable than it was before.

Polishing Step 1: Honing

After the initial production stage is complete and the resin is dry we pass each slab through our polishing machine to be initially honed. This is the initial step in the polishing process.

Heating

After honing, we pass each through our extremely high-temperature furnace. This is done to allow the resin applied in the defect-correction stage to penetrate more deeply into the stone and prepare the slab for the next resin application.

After the initial production stage is complete and the resin is dry we pass each slab through our polishing machine to be initially honed. This is the initial step in the polishing process.

Heating

After honing, we pass each through our extremely high-temperature furnace. This is done to allow the resin applied in the defect-correction stage to penetrate more deeply into the stone and prepare the slab for the next resin application.

Polishing:

After the resin application process is completed we start the polishing process proper. We do our polishing on an automatic line polishing machine where each slab undergoes abrasive polishing, again using materials imported from Italy, to give each slab the desired amount of brilliant shine.

After the resin application process is completed we start the polishing process proper. We do our polishing on an automatic line polishing machine where each slab undergoes abrasive polishing, again using materials imported from Italy, to give each slab the desired amount of brilliant shine.

Inspection:

After completing our meticulous production process, taking anywhere from 1-2 months, the slabs are finally ready for inspection. In this step the slabs are each inspected by another highly specialized team to search for any defects or imperfections. If any problems are identified we’ll have to start the entire process again, starting with defect remediation, then resining and polishing. Once slabs are finally approved we’ll take photos and make them available on our website for you to purchase.

After completing our meticulous production process, taking anywhere from 1-2 months, the slabs are finally ready for inspection. In this step the slabs are each inspected by another highly specialized team to search for any defects or imperfections. If any problems are identified we’ll have to start the entire process again, starting with defect remediation, then resining and polishing. Once slabs are finally approved we’ll take photos and make them available on our website for you to purchase.

We hope this has helped you understand how much work from various teams is involved in our mission to bring you the finest quality natural stone in the industry. Far from just digging rocks out of the ground each step of the process involves trained professionals,cutting-edge products, and the kind of industry know-how that you can only get through years of experience. Brothers in Granite appreciate our customers and we only want to bring you the best! We value your trust in our brand and hope you continue to enjoy our exceptional products.